Contents

- What is F-Gas?

- What is GWP?

- HFC Phase-down

- Owner’s Obligation for F-Gas Regulation

- Finding F-Gas certified suppliers

- Key Refrigerant Phase Down Dates

- Moving to low GWP Refrigerants

- Energy Efficient Refrigerant Selection

What is “F-Gas”?

- “F-Gas” is any Fluorinated greenhouse gas, commonly abbreviated to HFC or PFC which have several industrial uses as well as refrigerants

- All refrigeration equipment owners must be compliant with the 2014 EU F-Gas regulation – EU 517/2014

- Whilst they have very good refrigerating properties, F-Gases all have very high GWPs

- Alongside the EcoDesign Regulations (ErP), The F-gas Regulations are a significant component of the EU “2050 Low Carbon Roadmap”

What is GWP?

GWP is “Global Warming Potential” and all substances have a GWP in the form of a number which is representative of its potential as a greenhouse gas by comparing it to CO2:

Example:

GWP of CO2:1

GWP of refrigerant R404A: 3922

This means that every kg of R404A released into the atmosphere has the same greenhouse effect as 3922 kg CO2.

HFC Phase-down

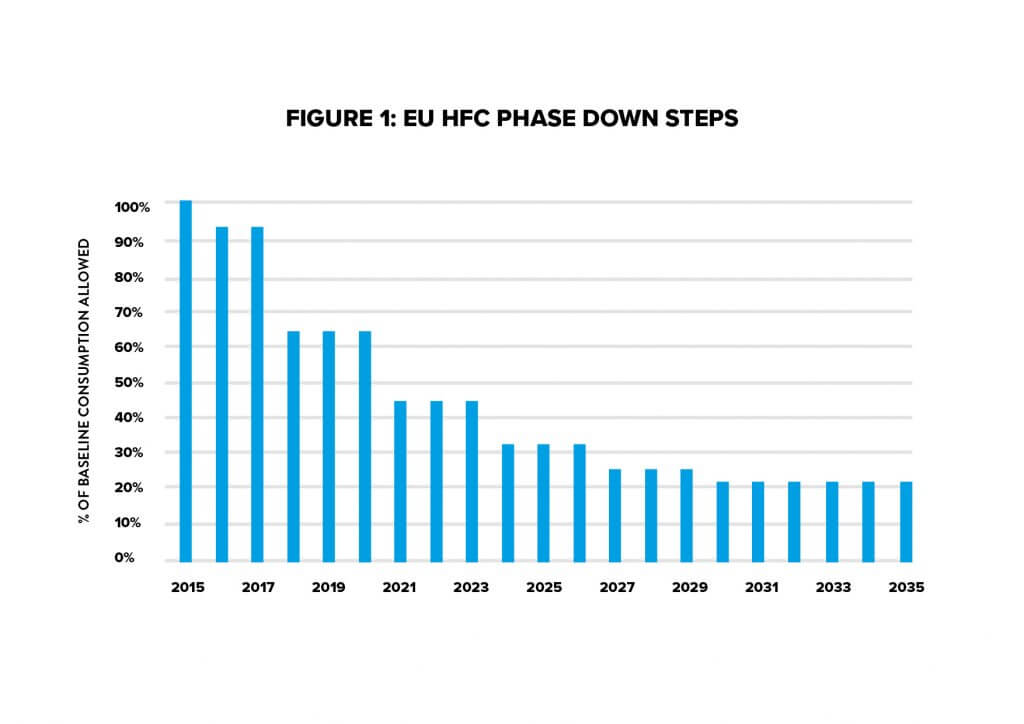

In Europe, we are now embarked on a Phase-down programme which runs from 2015 to 2030.

During phase-down, the amount of HFCs placed on the market will be gradually reduced to around 21% of the starting figure by 2030.

This is achieved by applying a quota system which considers the GWP as well as the mass of refrigerant, so if a quota holder has an allocation of 100,000 tonnes CO2e (CO2 “equivalent”), the physical amount of refrigerant equates to 25.5 tonnes R404A (GWP 3922) or 48 tonnes R410A (GWP 2088) or 70 tonnes R134a (GWP 1430).

The phase-down chart shows the reductions in terms of percentages and the first big drop is 2017-2018 where the availability is down to 63% of the starting figure. If at the start, the average GWP was 2,000, then by 2018, the average GWP should be down to 1260.

By choosing low GWP refrigerants for new equipment and by avoiding or converting from high GWP options, the overall average GWP will quickly reduce.

Your (Owner’s) Obligation

Prevent refrigerant leakages:

- Ensure refrigerant leak tests are carried out at the necessary frequency

- Ensure any refrigerant leaks are repaired without delay

- Ensure proper recovery during chiller repair/maintenance and at end of life

- Maintain proper records of F-Gas usage for every machine

Containment

- Refrigerant leak tests

Leak tests must be undertaken on a regular basis by a competent and F-Gas certified technician from a certificated company. The frequency of leak tests is determined by the CO2e of the weight of the refrigerant charge:

| Charge CO2e | Leak check frequency |

| 500 tonnes or more | At least every 3 months |

| 50 to 499.99 tonnes | At least every 6 months |

| 5 to 49.999 tonnes | At least every 12 months |

If a fixed leak detection system is installed, the leak check frequency is halved, so a 3 monthly frequency becomes 6 monthly.

A chiller with 25 kg R410A (2088) will require 6 monthly leak checks, whereas a chiller with 25 kg R134a (1430) needs 12 monthly leak checks.

- Refrigerant leak repairs

Where a leak is found, it must be repaired “without delay”, or the chiller must be safely decommissioned, and the remaining charge recovered.

- Refrigerant leak detection

Operators of equipment with an F-Gas charge in excess of 500 tonnes of CO2e need to ensure that the equipment has an automatic leak detection system which will alarm in the presence of an F-Gas leak. The leak detection system must be checked and calibrated at least every 12 months.

Refrigerant recovery

The regulation prohibits the release of any F-Gas into the atmosphere. The owner must ensure that the refrigerant is properly recovered by a certificated operative and into a designated “recovery” container. Recovery is necessary at the end of its life and may be necessary on occasions during the lifetime of the equipment to facilitate repair, maintenance or a charge check.

Record keeping

The owner must keep records relating to leak checks, F-Gas losses and additions, whether it is virgin or reclaimed gas, end of life recovery, dates and the identity of the company undertaking the work and their certificate number. Every machine should have its own record/log.

Training and certification

Anyone who undertakes any work on the equipment must hold a current F-Gas Category 1 certificate. This includes, installation, servicing, maintenance, repair, leak checking, recovery and decommissioning. The company which employs the certificated person must also be certificated and listed on a national register.

Labelling

All products and equipment which contain F-Gases must carry a label which meets with the requirements listed in the regulation.

The label must include:

- That the equipment contains an F gas

- The industry name for the F gas, or the chemical name if there isn’t an accepted industry name

From 2017 the label must also state the:

- Mass of F gas in the equipment (in kg)

- Carbon dioxide (CO2) equivalent mass of F gas in the equipment (in tonnes)

- GWP of the F gas

- If F gas is ‘hermetically sealed’ within a product, the label must also state that’s the case

Finding F-Gas certified suppliers

ICS Cool Energy’s extensive international network of F-Gas qualified service engineers will ensure you are F-Gas compliant. F-Gas compliance comes as standard with every Planned Preventative Maintenance Programme undertaken and the frequency of your F-Gas checks will be in line with your CO2 charge.

High GWP refrigerant phase down key dates

- (Affects Chillers)

Ban on new equipment with refrigerant with GWP > 2500.

- 2020 January 1st: (Affects Chillers)

Service and maintenance ban of existing equipment with virgin refrigerants with GWP >2500 where charge is greater than 40 tonnes CO2e. (Equates to 10 kg R404A)

- 2020 January 1st: (Not Chillers)

Ban on movable room air conditioners with refrigerant with GWP >750

- 2022 January 1st: (Not Chillers)

Ban on new hermetic and multi-pack centralised systems over 40 kW capacity with refrigerant with GWP >150.

- (Not Chillers)

Ban on refrigerators & freezes for the storage, display or distribution of products in retail and food service (commercial use) with refrigerant with GWP >150.

- (Not Chillers)

Ban on single split air-conditioning systems containing less than

3 kg refrigerant WITH GWP >750.

- 2030 January 1st: (Affects Chillers)

Ban on the use of refrigerants, recovered, reclaimed and/or recycled with GWP >2500 for service and maintenance.

Moving to low GWP refrigerants

As well as taking care of your F-Gas compliance and obligations, our service engineers can convert your existing plant to low GWP refrigerants, so you can rest assured that you are compliant with all refrigeration associated legislation and benefit from reduced operative and maintenance costs.

ICS Cool Energy can also support you with low GWP refrigerant selection on any new refrigeration plant you plan to acquire.

Energy Efficient Refrigerant Selection

Refrigerant Selection can have an important effect on the energy efficiency of your chiller, the video below details the importance of choosing the correct refrigerant and an overview of the phase-down timeline