Updated: May 20, 2025

Why Seasonal Energy Performance Ratio (SEPR) Matters for Process Cooling.

The Manufacturer’s Perspective on Energy Efficiency, Compliance and Sustainability

In the world of process cooling, selecting the right equipment is no longer just about capacity or initial cost. Increasingly, it’s about energy performance, compliance with evolving regulations, and long-term sustainability. That’s where the Seasonal Energy Performance Ratio (SEPR) becomes a critical factor, particularly for plant and facilities managers who need their systems to tun efficiently 24/7, all year round.

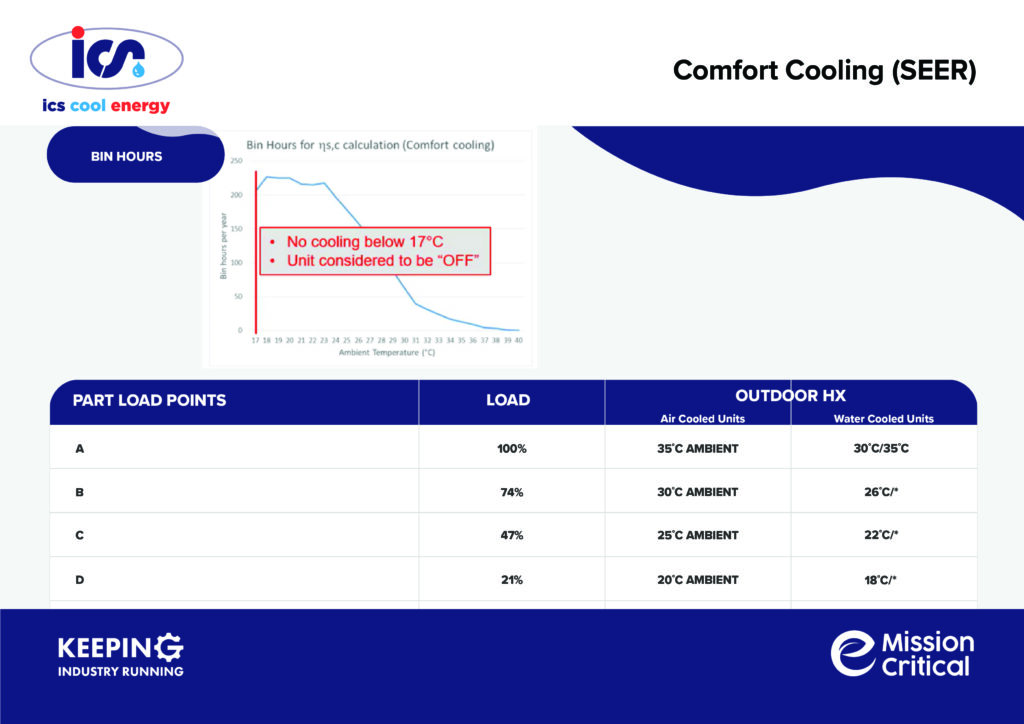

Unlike the Seasonal Energy Efficiency Ratio (SEER), which applies to air-conditioning and comfort cooling systems operating intermittently, SEPR was developed specifically to measure the real-world performance of industrial process cooling equipment, that typically operate at 80–100 percent load throughout the entire year.

It accounts for high load factors and continuous operation, reflecting the true conditions under which this equipment functions. This distinction is important: using comfort cooling equipment in a process environment not only leads to inefficiencies but can also result in non-compliance with regulatory standards. For plant managers, choosing SEPR-certified systems isn’t just good practice, it’s essential and has real impact on the equipment performance, total as well as operational costs of ownerships.

Understanding SEPR Classifications

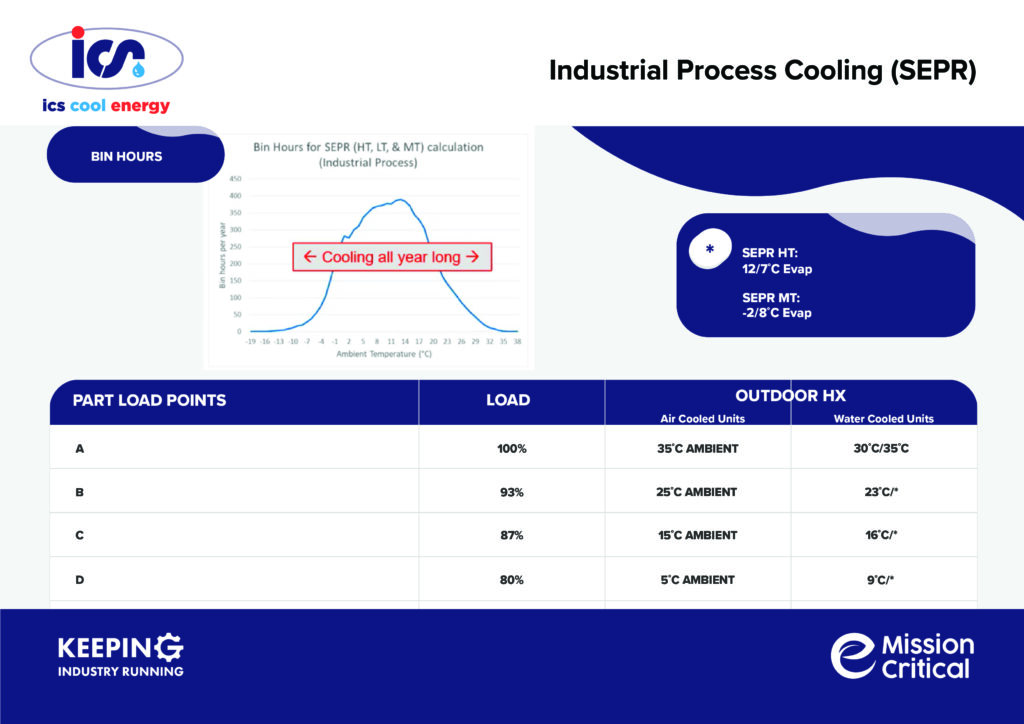

SEPR is divided into three categories based on the application’s temperatures requirements:

- SEPR HT (High Temperature) applies to systems operating between 7°C and 12°C, with mandatory compliance within this range.

- SEPR MT (Medium Temperature) applicable to systems functioning between -8°C and 7°C.

- SEPR LT (Low Temperature) addresses systems operating below -25°C.

These categories ensure that systems are accurately assessed against realistic performance benchmarks within their intended operational range. Key manufacturers of industrial chillers design and test equipment to align with these classifications, providing verified efficiency across process applications, from pharmaceutical production to food and beverage processing.

How SEPR Measures Real Efficiency

SEPR evaluations consider the system’s cooling output (kilowatts) to electrical energy input over a full calendar year of operation – 8,640 operational hours annually – factoring in real ambient conditions and varying load profiles. Using a “bin hours” methodology, the assessments begins at as low as -19°C (compared to 17°C for SEER), delivering a far more accurate measure of performance.

It’s important that process equipment meets these stringent requirements through continuous testing and third-party certification. Independent assessments, such as those conducted by Eurovent, add credibility and allow equipment buyers to make informed decisions with full confidence in the product’s performance and compliance status.

Compliance is Not Optional

SEPR compliance is required under the Eco-Design Directive in the United Kingdom and European Union. Both manufacturers and equipment purchasers bear responsibility for adhering to these regulations.

From a cooling systems manufacturer standpoint, it’s their duty to ensure the products meet regulatory standards and must communicate compliance status transparently to customers. This means documentation, performance data, and third-party certifications as proof of compliance. For plant managers, verifying this documentation should be essential.

Choosing non-certified or non-compliant equipment could expose the operation to serious risks. Detailed records of SEPR compliance, including testing results, certifications, and communications, forms the basis of a strong due diligence strategy for both buyers and suppliers.

A Strategic Choice for Long-Term Risk Mitigation

In high-dependency sectors such as pharmaceuticals, chemicals and food production, cooling equipment is mission-critical. The stakes are too high to risk equipment that has not been independently certified for real-world process energy efficiency and performance.

By choosing SEPR- certified systems from a compliant manufacturer, plant managers reduce the risk of downtime, ensure operational stability, and contribute meaningfully to sustainability goals. In our experience, short term savings associated with uncertified, or not-for-process-certified systems are quickly outweighed by the long-term costs of inefficiency, massively reduced reliability and non-compliance.

Compliance as Proof of Integrity

SEPR is more than a technical rating, it’s a framework for responsible decision-making. As energy regulations tighten and performance expectations rise, SEPR-certified equipment ensures the cooling systems are efficient, reliable and future-ready. By choosing SEPR-certified systems from a compliant manufacturer, plant managers maximise operational stability and contribute meaningfully to sustainability goals.

But with more organisations publicly committing to climate action and environmental pledges, procurement decisions must match those ambitions. Choosing non-compliant or uncertified systems raises difficult questions: is this result of poor advice, limited knowledge, or deliberate trade-off for short terms savings? Either way, it casts doubt on the credibility of public sustainability commitments and claims. Engineering and procurement teams that overlook SEPR compliance may not only compromise operational performance, they may also damage reputations, lose future contracts, and undermine the business’ broader environmental strategy.

Related Articles

December 17, 2025

Turning Low Ambient Temperatures into Savings.

Free Cooling: the Most Cost-Effective and Environmentally-Friendly Way to Cool Processes and Buildings Improving the performance of industrial and commercial facilities’ systems is rightly a...

Read More

November 26, 2025

Why Flexible Financing Options Matter More Than Ever

Navigating Investment in UK Manufacturing As the UK government prepares to deliver the next budget, uncertainty is the prevailing mood, felt on factory floors and...

Read More

October 30, 2025

Meeting the Pressures of Modern OEM Design. Why Accredited Cooling Systems Make the Difference

Tight budgets, compressed timelines, and rising expectations: how OEMs can help ensure reliability and performance of their solutions through smarter cooling partnerships. Original equipment manufacturers...

Read More