Ready to talk?

Chiller Sales

Request a Quote

Process chillers

Process chillers are designed and built from the ground up to be more reliable, operate within tighter specified tolerances and to be more robust for continued operation when compared to chillers designed for HVAC. Our i-Chillers are specifically designed to cope with the rigours of manufacturing and critical processes.

Process chillers may cost slightly more than equivalent HVAC or comfort chillers but are significantly better value and fit for purpose in a critical process. A process chiller will deliver more accurate leaving water temperature, operate trouble free for longer, have a lower op-ex cost and a greater residual value.

Chillers built for process

Our range of process chillers is designed specifically for process, with features such as unique finned coil evaporators immersed inside the cold-water tank, making them less susceptible to freezing and able to cope with variable load and process fluctuations. The large integrated cold side buffer tank enables closer temperature control for process tolerance and reduces wear and tear from compressor start and stop operations.

i-Chillers have high-pressure pumps as standard to cope with the more complex pipework found in process applications. Being fully enclosed in robust steel panels not only protects but creates a smaller footprint for ease of access and plug & play installation.

Our approach

Since 1989 we have created bespoke temperature control solutions across all manufacturing, industrial and critical process applications. With a network of highly experienced technical engineers nationwide, we will visit your site to understand your exact application needs and audit your facilities and potential constraints to develop the optimum solution for your circumstances. We can design, install, commission and project manage bespoke turnkey solutions and provide full, tailored 24/7 maintenance & breakdown support with our nationwide service & hire team.

Process chiller FAQ's

What does the chiller warranty include?

Which refrigerants do you use?

Can you modify the chillers?

Do you offer a chiller service plans?

Is your equipment ATEX rated?

What is the difference between process and HVAC chillers?

What does a process chiller do?

What is a packaged chiller?

Chiller Sales Case Studies

Low GWP chillers Temporary chiller hire

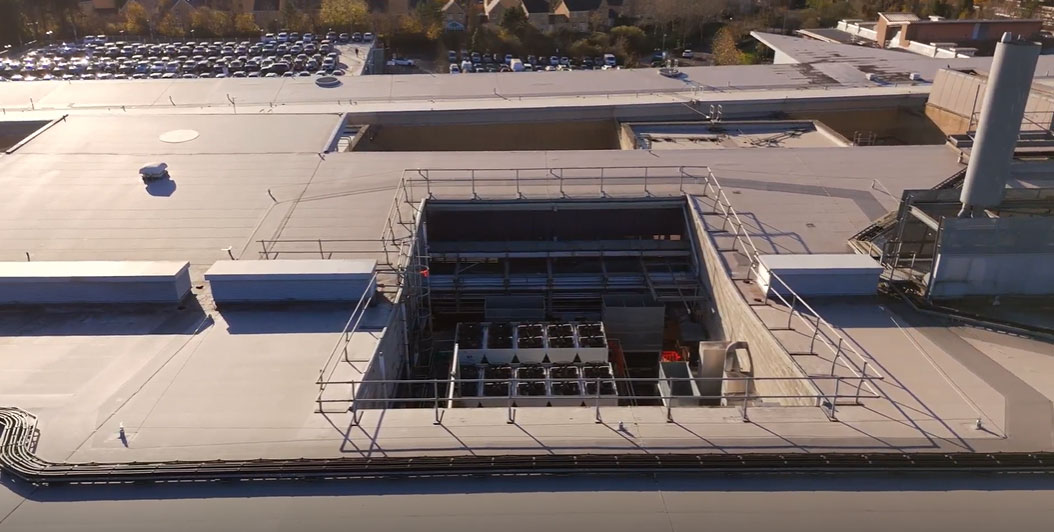

Keeping Cool Under Pressure: Comprehensive Cooling Infrastructure Upgrade at Princess Royal University Hospital in Orpington

Read case study

Process chillers Your Process Chiller Options

Overcoming Logistical Challenges to Upgrade Critical Cooling Systems for a Hospital in Scotland

Read case study

Chiller hire Chiller hire London Emergency chiller hire Process chillers Temporary chiller hire

Contingency Planning and Rapid Chiller Hire Ensures Continuous Operation of MRI Scanners at London Hospital

Read case study

We provide reliable temperature control solutions that fit your industry and application. Please choose your industry below to find out how we can help.

Related Categories

Air cooled chillers

As part of our extensive range of process cooling options, we offer air cooled chillers which are suitable for process cooling and air conditioning applications. With capacities from 17kW to multi-megawatts, these air cooled chillers are capable of cooling processes and buildings of any size and design. Air cooled chillers provide the same function and consist of the exact same design as water cooled chillers, with the main difference being the way heat is transferred into the air as opposed to a water loop. Our range of scroll compressor, air cooled chillers have multiple benefits. These include low footprint, high efficiency, and low noise, ensuring the right product for your application. We've been providing temperature control solutions and service support since 1989, designing turnkey solutions, and working with businesses to create a solution for them, with our standard range in stock for immediately delivery.

Ammonia chillers

For a complete packaged system where deep freezing is necessary, our air-cooled ammonia chiller range, the i-Chiller Process LTn, is specifically designed for processes from -12°C down to -30°C. With a simple plug and play installation, the i-Chiller Process LTn can be ready to use in no time at all. The unit is designed for outdoor installation, and the ultra compact, weatherproof, galvanised steel body, keeps the unit nicely contained and easy to position in most environments. The i-Chiller Process LTn delivers unrivalled reliability and safety, using the latest state of the art freezing technologies. The dual circuit, inverter driven semi-hermetic screw compressor allows for low charge ammonia refrigeration, without sacrificing freezing capacity or energy efficiency. Whether it's for frozen produce, meat, fish, fruit and vegetables, or pharmaceutical storage, these highly efficient ammonia chillers will help contribute towards your ESG targets through lowering your energy consumption by using the natural, zero global warming potential (GWP) refrigerant (R717). We will design, install, commission, and project manage bespoke turnkey solutions and provide full, tailored 24/7 maintenance and breakdown support with our fully qualified maintenance engineers. <strong>Complete packaged system</strong> Compared to most ammonia chillers, all of our units are compact and contained within a galvanised steel body which offers exceptional flexibility for ease of installation, operation, and maintenance. As a means to maintain temperature with precise control, you can pair the i-Chiller Process LTn with our cold storage units to provide the most flexible way to store your frozen produce. <strong>Energy efficient and sustainable</strong> R717 refrigerant grade ammonia is one of the most efficient refrigerants available, and perfect for organisations wanting to improve their sustainability footprint. Being a natural refrigerant, the climate friendly R717 has a zero rating for ozone depletion and global warming potential. These chillers also consume no water as part of the process. The i-Chiller Process LTn features Variable Speed Drives (VSD) installed as standard. These vary the output depending on the demands put on the system, and further improve the efficiency of your process. <strong>Safety and monitoring</strong> The i-Chiller Process LTn units are equipped with a range of safety features, including pressure sensors, temperature sensors, and automatic shut-off valves, ensuring safe and reliable operation. With a digital control panel and web interface, the unit collects performance data that can be monitored externally on any browser or mobile device.

Low GWP chillers

With environmental concerns taking centre stage in the public eye, and the decision making processes in every aspect of business, it is important to be aware of the options available to improve the sustainability of your process. Our range of low global warming potential (GWP) chillers use energy efficient designs and low GWP refrigerants to improve the sustainability of your chillers. With high tariffs being applied to high GWP refrigerants, and rising costs of energy, it also makes financial sense to consider the environmentally friendly options available. We have started the e-Mission critical initiative, dedicated to educating businesses on environmentally friendly solutions to their process and air conditioning requirements, making it the perfect partner for your next temperature control project. <strong>Our energy approach</strong> Since 1989 we have created bespoke temperature control solutions across all manufacturing, industrial, and critical process applications. With a nationwide network of highly experienced technical engineers, we will visit your site to understand your application needs, audit your facilities and potential constraints, and develop the optimum solution for your individual circumstance. We can design, install, commission, and project manage bespoke turnkey solutions and provide full, tailored, 24/7 maintenance, and breakdown support.

Planet friendly process cooling

Designed specifically for industry applications, the planet friendly i-Chillers feature the lowest global warming potential (GWP), and ozone depleting potential (ODP) refrigerants. Unlike traditional HVAC units, our i-Chiller range has been designed with process applications in mind. As such, they can operate faultlessly and maintain accurate temperature control 24/7 under highly differing, and abruptly fluctuating operating conditions. The planet friendly i-Chillers represent continuous progress in our e-Mission critical initiative. This ambition encapsulates several intrinsically linked energy-saving concepts and a range of next generation low GWP and ODP refrigerants, helping our customers to save energy, reduce costs, and lower their carbon footprint in the process. Within the planet friendly portfolio, our customers can find solutions to achieve increased productivity, high temperature control precision, and elevated product quality with highest environmental awareness. <strong>Futureproof your operation</strong> The fluorinated refrigerants phase down in the UK and Europe requires that the production of virgin fluorinated gases (HFCs) is gradually reduced, and HFC consumption is cut 79% by 2030. This makes it even more vital to make a timely transition to high efficiency refrigerants with a low GWP. <strong>R-454B Refrigerant </strong> The R454B refrigerant is a non ozone depleting HFO/HFC* blend with a GWP level of 467, the lowest among the refrigerants available today for scroll compressor technology. R454B offers 76% reduction in direct GWP impact against R410A and 34% reduction against R32 refrigerant. The chillers with R454B will deliver higher seasonal efficiency compared to R410A, offering up to 6% improvement, and offer more application flexibility compared to R-32 thanks to wider operating maps. *HFO – Hydrofluoroolefins; HFC – Hydrofluorocarbons <strong>R-290 Refrigerant</strong> The R290 is a non-toxic natural refrigerant which causes no damage to the ozone layer. It has a GWP of 3 and excellent thermodynamic properties, offering higher energy efficiency ratio (EER) versus traditional alternatives. Applying R290 allows customers to avoid carbon taxes, benefit from national incentives, and future-proof their investment as R-290 is exempt from the HFC refrigerant phase out programmes. <strong>R-717 (Ammonia) refrigerant </strong> The R717 (Ammonia or NH3) is a natural refrigerant with zero GWP and ODP. Its performance allows for deep freezing processes requiring heat transfer fluids between -12°C and -30°C.

Water cooled chillers

Our water cooled chiller range covers capacities from 17-4 MW and is suitable for process and HVAC applications supporting temperatures from -10°C to 20°C. Available in low noise, low footprint, and high energy efficiency options across all ranges, our water cooled chillers provide manufacturers and businesses a solution for their unique circumstances and requirements. We have been providing process and air conditioning solutions to businesses since1989, working with them to ensure they get a tailored, full turnkey solution. <strong>Chillers specifically built for process</strong> Our range of process chillers are designed specifically for process, with unique features such as finned coil evaporators immersed inside the cold-water tank, making them less susceptible to freezing, and able to cope with variable load and process fluctuations. The large integrated cold side buffer tank enables closer temperature control for process tolerance, and reduces wear and tear from compressor operations. i-Chillers have high-pressure pumps as standard to cope with the more complex pipework found in processes applications. Being fully enclosed in robust steel panels, this not only protects, but creates a smaller footprint for ease of access and plug and play installation. <strong>Our approach</strong> Since 1989 we have created bespoke temperature control solutions across all manufacturing, industrial, and critical process applications. With a nationwide network of highly experienced technical engineers, we will visit your site to understand your exact application needs, audit your facilities and potential constraints, and develop the optimum solution for your individual circumstance. We can design, install, commission, and project manage bespoke turnkey solutions. We provide full, tailored 24/7 maintenance & breakdown support with our nationwide service & rental team.

Low temperature chillers

Our low temperature chiller range contains both packaged, low temperature versions of our i-Chiller range, as well as bespoke, large chillers (both air and water cooled) capable of reaching temperatures of -40°C for specialist process applications. Fully eco-design compliant, our low temperature chiller range combines environmental responsibility with features such as electronic expansion valves and variable fan speeds as standard to ensure precise temperature control, even at the extreme temperatures provided by these units. We have been designing and manufacturing specialised low temperature chillers to process manufacturers for over thirty years, designing complex solutions for businesses of all sizes and providing aftersales support with a nationwide network of service engineers. <strong>Built for low temperature applications</strong> Unlike competitors who modify existing chillers, the low temperature chiller range is purpose built from the ground up to ensure it can handle the unique challenges faced by chillers providing a extremely low return temperatures, with features such as a specially designed condenser and fully welded design ensuring the the units are capable of handing the stress. Our low temperature units have been custom built to ensure the best possible compatibility with your existing or designed low temperature process applications. Our VLT units come equipped with a Siemens PLC controller, allowing it to communicate with a wide range of process equipment.

Free cooling chillers

Free Cooling allows businesses to recover up to 80% of their process cooling energy costs by utilising lower ambient temperatures to cool their process application and reducing the need to power the chiller. Available as independent units or integrated with your process chiller, free coolers can be retrofitted into your existing process or installed as part of a turnkey solution. Working with businesses in the manufacturing and facilities management industries, we have lowered their energy costs and reduced their environmental impact through free cooling systems. Given the intrinsically process-heavy nature of the UK’s industrial manufacturing, process cooling is one of the biggest costs incurred. For many industrial end-users, process cooling is achieved solely via an air or water-cooled chiller or cooling tower. However, all industrial applications with a water leaving temperature of 10°C or more – regardless of sector – can start to be cooled via the external ambient air temperature, rather than by electro-mechanical refrigeration, thanks to a process known as free cooling. <strong>Up to 80% energy savings</strong> One of the stand-out benefits of a free cooling system is the sheer amount of energy – and therefore utility bills – it can save. While free cooling can bring about a reduction in energy consumption for any process cooling application with a water leaving temperature of 10°C or more, it should be attractive to larger manufacturers, such as those working in the chemical and pharmaceutical sectors. Further costs can be saved due to the reduced load on the chiller – particularly the compressors and fans – as they are not worked as hard, or at all in some cases. As such, maintenance costs can be lower over the lifetime of the system. From a health and safety point of view, unlike cooling towers, free cooling systems pose no risk of legionella and therefore do not require additional water treatment costs beyond the norm to mitigate the risk of an outbreak.

Process chillers

Process chillers are designed and built from the ground up to be more reliable, operate within tighter specified tolerances and to be more robust for continued operation when compared to chillers designed for HVAC. Our i-Chillers are specifically designed to cope with the rigours of manufacturing and critical processes. Process chillers may cost slightly more than equivalent HVAC or comfort chillers but are significantly better value and fit for purpose in a critical process. A process chiller will deliver more accurate leaving water temperature, operate trouble free for longer, have a lower op-ex cost and a greater residual value. <strong>Chillers built for process</strong> Our range of process chillers is designed specifically for process, with features such as unique finned coil evaporators immersed inside the cold-water tank, making them less susceptible to freezing and able to cope with variable load and process fluctuations. The large integrated cold side buffer tank enables closer temperature control for process tolerance and reduces wear and tear from compressor start and stop operations. i-Chillers have high-pressure pumps as standard to cope with the more complex pipework found in process applications. Being fully enclosed in robust steel panels not only protects but creates a smaller footprint for ease of access and plug & play installation. <strong>Our approach</strong> Since 1989 we have created bespoke temperature control solutions across all manufacturing, industrial and critical process applications. With a network of highly experienced technical engineers nationwide, we will visit your site to understand your exact application needs and audit your facilities and potential constraints to develop the optimum solution for your circumstances. We can design, install, commission and project manage bespoke turnkey solutions and provide full, tailored 24/7 maintenance & breakdown support with our nationwide service & hire team.