Whether it’s geopolitical tensions, extreme temperatures, price spikes or pressure on global supply chains, businesses continue to operate in an increasingly unpredictable environment in 2026. And “Continue” is the key word. In 2022, manufacturers faced record-high energy prices, which subsequently led to record-high inflation and continues to be felt today. Moreover, these challenges are coupled with increasingly common weather anomalies. These include record-high temperatures last summer and heavy rainfall that is set to place eight million properties at risk of flooding by 2050, compared with more than six million properties today, according to Environment Agency data estimates.

Challenge – and the solution

This period of “record-highs”, and the instability it brings, is especially concerning for manufacturers that rely on HVAC and process temperature control, where even a short loss of cooling or heating can quickly bring production to a halt. In this context, a strong contingency plan is no longer optional in manufacturers’ operational resilience strategies.

Even a well-maintained plant can be affected by factors outside a manufacturer’s control. Power failure, extreme temperatures, floods, accidental damage or delays in sourcing replacement parts can all compromise production if there is no plan in place.

When are contingency plans most beneficial?

A contingency plan can be critical in a wide range of scenarios, including:

- Extreme weather events such as flooding or heatwaves

- Power outages or unstable electrical supply

- Planned maintenance on critical plant

- Unexpected failure of chillers, boilers or heat pumps

- Refrigerant loss or mechanical breakdown

- Increased production demand that pushes systems beyond capacity

Aligning on the right contingency plan

An effective contingency strategy should reflect the systems that are critical to production. These commonly include:

- Cooling contingency plans for process cooling, data driven manufacturing and controlled environments

- Heating contingency plans to maintain working conditions, protect processes and prevent frost damage

- Temporary plant hire strategies that integrate with existing systems

- Planned maintenance contingency to maintain output while permanent systems are serviced

- Partnership with a specialist supplier to ensure temporary heating and cooling solutions are specified correctly, tested in advance and available when required.

Futureproofing manufacturing

Having the right contingency plan is also relevant when it comes to futureproofing, especially in the context of energy prices. In a recent article, Make UK highlighted energy costs as one of the biggest barriers to manufacturing growth. Without action, high energy prices risk weaker investment, reduced competitiveness and the gradual decline of key industries. The impact is felt most strongly across regional industrial heartlands, where manufacturing underpins productivity, jobs and supply chains.

In this context, contingency planning is not only about responding to emergencies. It is about protecting productivity, reducing exposure to downtime and supporting more efficient, resilient operations in an increasingly challenging energy landscape. As part of this futureproofing, manufacturers can also gain greater control over operational costs, particularly during periods of dynamic increases in production demand.

Practical steps to improve manufacturing resilience

There are several practical actions manufacturers can take to strengthen contingency planning.

- Conduct a site and operations audit. Risk assessment should cover all operations. In manufacturing, process temperature is often critical, making chillers, boilers and heat pumps a priority. Understanding where and why equipment is used is essential.

- Record and share critical information. Audit findings should be documented alongside electrical and utility requirements. Information must be accessible to multiple people, with hard copies on site and additional copies stored off site, as systems or personnel may be unavailable during a crisis.

- Put a Plan B in place. With risks identified, manufacturers can work with a supplier to agree what contingency equipment is required and how it will be deployed. Availability is key, so support must be available around the clock.

- Complete remedial works in advance. Temporary equipment requires suitable connections. Simple preparatory works such as installing pipework or power supplies can dramatically reduce response time during an emergency.

- Plan access and equipment location. Temporary chillers or heaters need space and clear access. Whether equipment is positioned in a plant room, yard or car park, access routes and positioning should be agreed and recorded in advance.

Activating a contingency plan

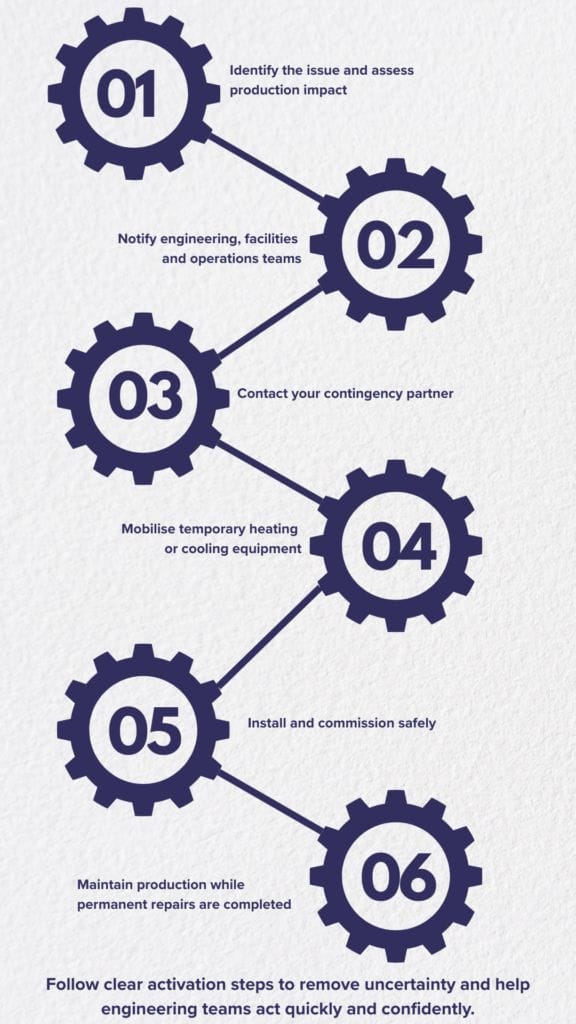

A clear activation process helps manufacturers respond quickly to system failures and minimise the risk of unplanned downtime. Engaging a specialist provider such as ICS Cool Energy enables rapid access to temporary heating and cooling equipment, supported by technical expertise and emergency response.

ICS Cool Energy provides process temperature control solutions for hire, sale and service, alongside emergency support available 24/7, 365. Temporary heating and cooling equipment can be deployed to support operations when permanent systems fail or are unavailable.

A typical activation process includes:

- Identify the issue and assess production impact

- Notify engineering, facilities and operations teams

- Contact your contingency partner

- Mobilise temporary heating or cooling equipment

- Install and commission safely

- Maintain production while permanent repairs are completed

- Follow clear activation steps to remove uncertainty and help engineering teams act quickly and confidently.

Case study: rapid response contingency planning in practice

A global contact lens manufacturer had previously developed a contingency plan as part of a planned maintenance agreement. Production lines were prepared in advance to accept temporary cooling equipment, allowing rapid installation without disruption.

When a chiller later ran low on refrigerant, an ICS Cool Energy engineer attended site to resolve the issue while a temporary cooling unit was installed simultaneously. Production continued throughout, with no loss of output or quality. The incident demonstrated how preparation can turn a potential shutdown into a controlled and routine response.

Another example of rapid response in a critical environment comes from a major hospital in London, where failure of the hospital’s chiller equipment threatened to disrupt the operation of vital MRI scanners, which require continuous cooling to operate. Any interruption could have had serious consequences for the hospital’s 24/7 diagnostic services.

In this case, ICS Cool Energy had already been in regular contact with the hospital’s estates team, engaging in proactive contingency planning that included detailed surveys and assessments to prepare for potential failures. When the chiller malfunction occurred, the results of these contingency surveys enabled ICS Cool Energy to rapidly assess the hospital’s cooling needs and deploy an industry-grade i-Chiller 80 kW unit from its hire fleet.

The ICS team managed logistics, including lifting the equipment to rooftop location out of hours to avoid disrupting ambulance access. As a result, the hospital’s MRI scanners remained fully operational, preventing delays in patient diagnosis and treatment. Maintained operation was supported by a long-term hire agreement, with ongoing support and maintenance from ICS Cool Energy.

Related Articles

November 26, 2025

Why Flexible Financing Options Matter More Than Ever

Navigating Investment in UK Manufacturing As the UK government prepares to deliver the next budget, uncertainty is the prevailing mood, felt on factory floors and...

Read More

November 13, 2025

Winter Maintenance for Adiabatic Cooling Systems. Protecting Performance All Year

Seasonal maintenance is essential for safeguarding adiabatic cooling systems against winter damage, ensuring reliable and efficient operation throughout the year. For engineers and production managers,...

Read More

October 30, 2025

Meeting the Pressures of Modern OEM Design. Why Accredited Cooling Systems Make the Difference

Tight budgets, compressed timelines, and rising expectations: how OEMs can help ensure reliability and performance of their solutions through smarter cooling partnerships. Original equipment manufacturers...

Read More