Free Cooling: the Most Cost-Effective and Environmentally-Friendly Way to Cool Processes and Buildings

Improving the performance of industrial and commercial facilities’ systems is rightly a priority for business organisations. Energy prices continue to rise, a reality that is increasingly uncomfortable—particularly as electricity costs are now 46% higher than the median paid by member countries of the International Energy Agency. This is more than just a statistic; combined with other market data, it translates into an everyday operational headache. The prospect of investigating and applying energy-efficient upgrades, decarbonising operations, or simply replacing older temperature control equipment can feel daunting.

Cooling and heating are critical in all manufacturing processes and the indoor environment, directly influencing operational efficiency, cycle times, product quality, and workforce productivity. These systems are fundamental to every production application, from food and beverage to plastics moulding, and cannot be overlooked or taken lightly.

High electricity costs and mounting pressures to reduce environmental impact mean that operating outdated, inefficient systems, which do not reflect the latest technological advancements, presents an ongoing operational risk, threatening margins, uptime, and reputation. Manufacturers facing higher bills, unpredictable demand, and constrained labour markets require solutions that deliver immediate efficiency, reliability, and long-term flexibility.

Realising the full potential of a process cooling system can unlock savings and improve operational efficiency. However, this demands a whole-life approach, one that recognises opportunities to reduce total system costs throughout the lifecycle, rather than focusing solely on initial outlay.

What is Free Cooling?

The concept of free cooling is far from new. In the past, we would cool down cars heated by the sun simply by opening the windows, allowing the cooler outside air to lower the temperature inside. The same principle applies to free cooling in industrial environments.

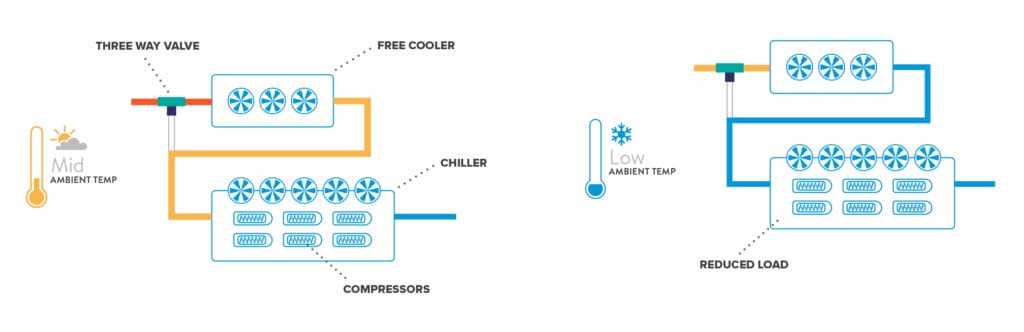

Any company or organisation with an externally sited chiller can benefit from free cooling. Whenever the outside temperature is sufficiently low to cool the process fluid without the need for the chiller’s mechanical cooling, a free cooling solution can be introduced. This may take the form of partial free cooling—where the chiller’s compressors continue to contribute to cooling—or full free cooling, where the load on the chiller is completely offset. By comparison, a chiller lacking free cooling capabilities must work continuously to achieve the same cooling effect.

When and How Does Free Cooling Work?

In the UK, Ireland, and much of Western Europe, the relatively cool climate and ambient temperatures allow for partial or full free cooling during much of the year. Substantial energy savings are possible, particularly between October and April, with electricity savings in some cases reaching up to 80%.

When the ambient air temperature drops just one degree Celsius below the process fluid return temperature, a three-way valve diverts the returning process fluid through the free cooling coil. In this coil, the cooler ambient air removes process heat and cools the fluid, this is known as partial free cooling. The fluid then passes through the chiller’s evaporator to reach the required set point temperatures, easing the demand on the chiller’s components and extending their operational life. Full free cooling is achieved as the ambient air temperature continues to fall and the fluid from the free cooler meets the process temperature required.

Do You Require a New Chiller or Can a Free Cooling Solution Be Added to Existing Plant?

Free cooling can be implemented either with a chiller featuring an integrated free cooling coil, or with a remote free cooler working in series with the chiller.

Free coolers can also be used as a cooling solution in its own right, or to provide free cooling for a significant proportion of the year when used in conjunction with a chiller.

As these systems are fully packaged, with integral controls, three-way valve and actuator, and bypass pipework, they can be readily installed on both existing systems and new builds. Moreover, no communication between the free cooler and the chiller is required, which in typical process cooling systems allows chillers to be offloaded for up to 90% of the year.

Solutions are available with multiple fixed fan speeds, inverter speed control, and Electronically Commutated (EC) fans to suit varying noise requirements. The unit control panels are designed for ease of use, offering a true ‘plug and play’ experience and connectivity. They can be configured to meet individual project requirements such as low noise, space limitations, and aesthetics, and can be integrated with Building Management Systems (BMS).

The Bottom Line Benefits of Free Cooling

In summary, free cooling provides a tangible solution for reducing mechanical energy consumption, lowering carbon emissions, minimising the workload on mechanical components, and, as a result, decreasing maintenance costs and extending the operational life of the cooling equipment. In the case of chillers, reduced load demands can also mitigate depreciation over the unit’s lifetime. Free cooling is straightforward to retrofit (space permitting) and can deliver rapid payback on new equipment.

Customers wishing to integrate free cooling into their systems, yet keen to avoid major capital expenditure, can take advantage of hire options or equipment-as-a-service offerings providing customers with a predictable monthly package subscription. This type of flexible, subscription-based agreement provides access to the latest temperature control technology, maintenance, and equipment exchange or upgrades, all with the flexibility of an operating expense. The flexibility of this business model can play a vital role in decision-making and in making the transition to more sustainable cooling.

Related Articles

November 26, 2025

Why Flexible Financing Options Matter More Than Ever

Navigating Investment in UK Manufacturing As the UK government prepares to deliver the next budget, uncertainty is the prevailing mood, felt on factory floors and...

Read More

October 30, 2025

Meeting the Pressures of Modern OEM Design. Why Accredited Cooling Systems Make the Difference

Tight budgets, compressed timelines, and rising expectations: how OEMs can help ensure reliability and performance of their solutions through smarter cooling partnerships. Original equipment manufacturers...

Read More

May 20, 2025

Why Seasonal Energy Performance Ratio (SEPR) Matters for Process Cooling.

The Manufacturer’s Perspective on Energy Efficiency, Compliance and Sustainability In the world of process cooling, selecting the right equipment is no longer just about capacity...

Read More