VARIABLE SPEED DRIVES

Controlling the flow of air and water in process temperature control systems is an effective, permanent way to meet the everchanging demands put on a system and enhance its efficiency.

We can install a Variable Speed Drive or VSD (an electrical/electronic system that provides infinitely variable speed control of AC induction motors).

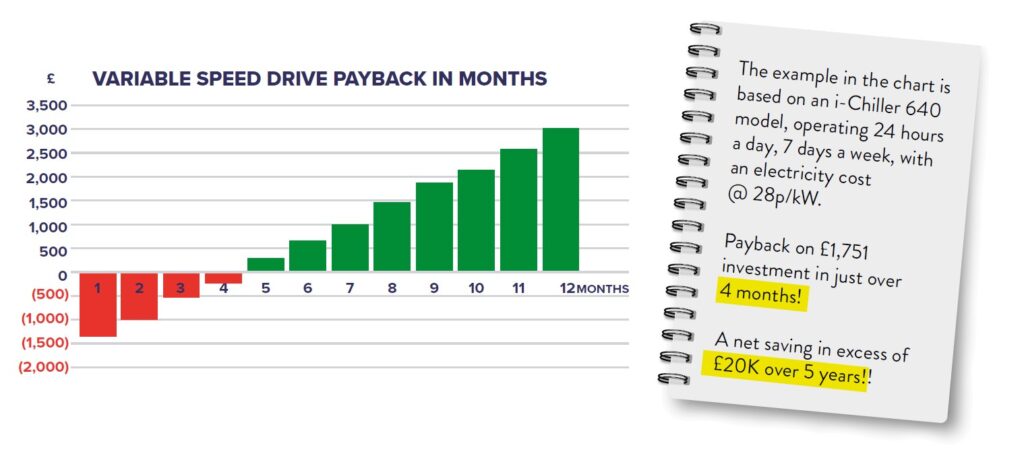

VSD’s can be installed to meet varying system flow rate requirements or just to increase energy efficiency. Payback on an installed system can be as little as 6 months.

By installing a Variable Speed Drive (VSD) – an electrical/electronic system that provides infinitely variable speed control of AC induction motors – you can meet varying system flow rate requirements or just increase energy efficiency.

Variable-speed technologies are applied by chiller manufacturers across product portfolios, but VSD technology can also be retrofitted to existing chillers, making it an excellent option for businesses looking to improve efficiency and reduce the energy consumption of their cooling systems.

Retrofitting VSD technology to an existing chiller involves installing a VSD drive between the motor and the electrical supply. The VSD drive adjusts the motor speed to match the cooling load, reducing energy consumption and costs.

Payback on an installed VSD system can be as little as 4-6 months.