Meeting the Pressures of Modern OEM Design. Why Accredited Cooling Systems Make the Difference

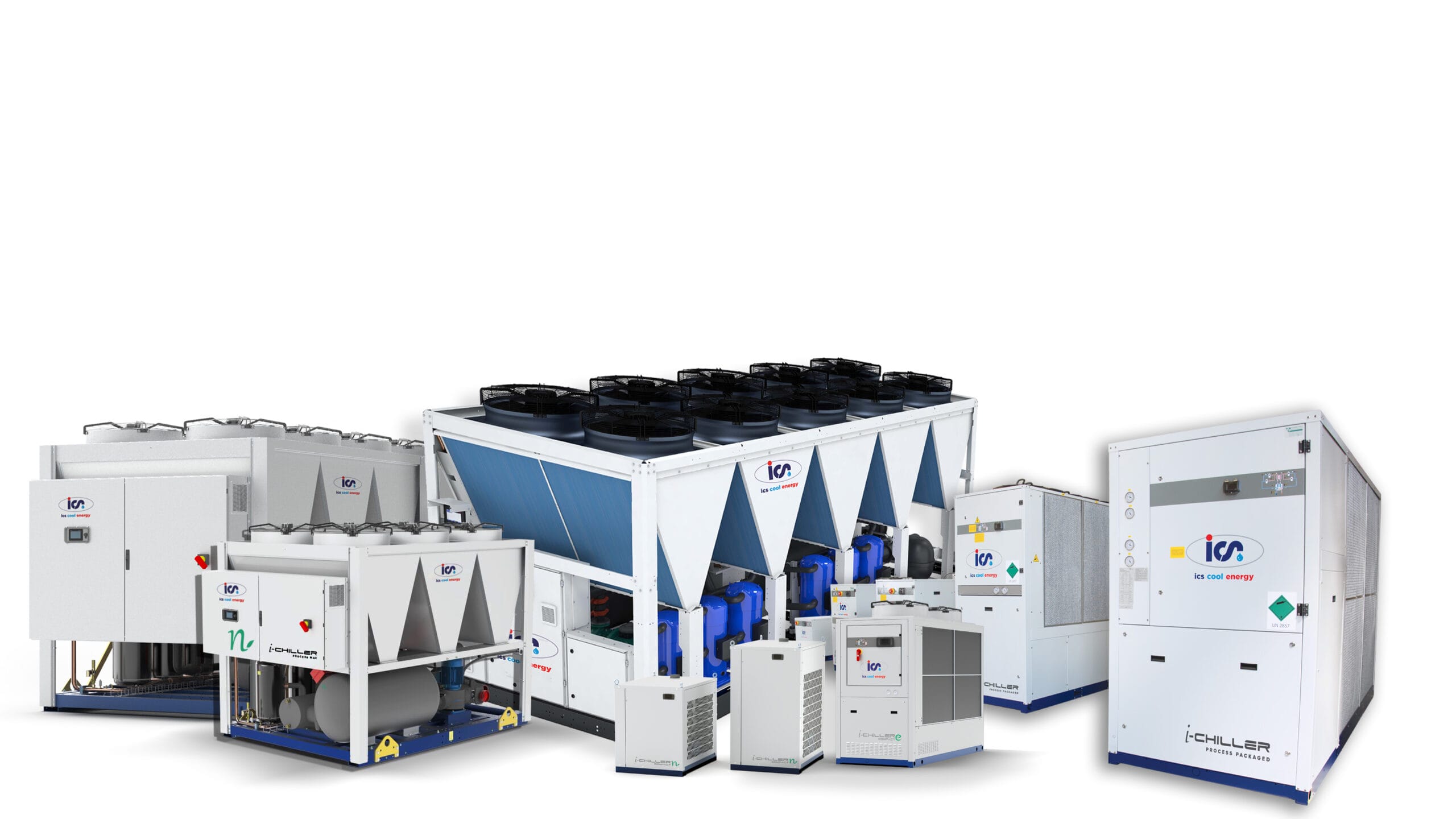

Tight budgets, compressed timelines, and rising expectations: how OEMs can help ensure reliability and performance of their solutions through smarter cooling partnerships. Original equipment manufacturers (OEMs) are under constant pressure to deliver machines that are not only technically robust but also innovative, reliable, and cost-effective. A match made in heaven, as they say. Whether designing … Read more